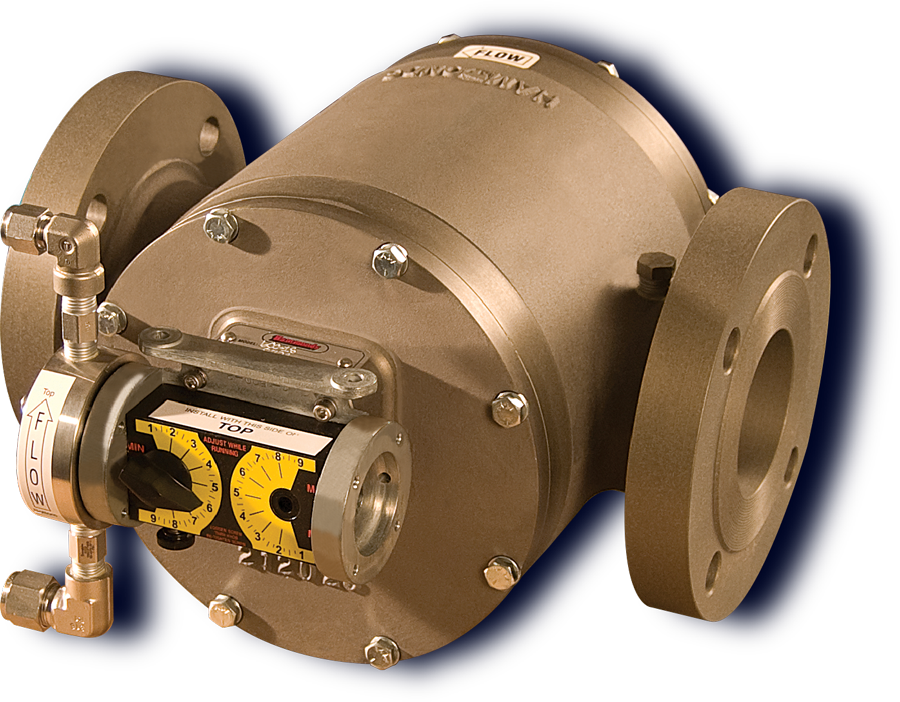

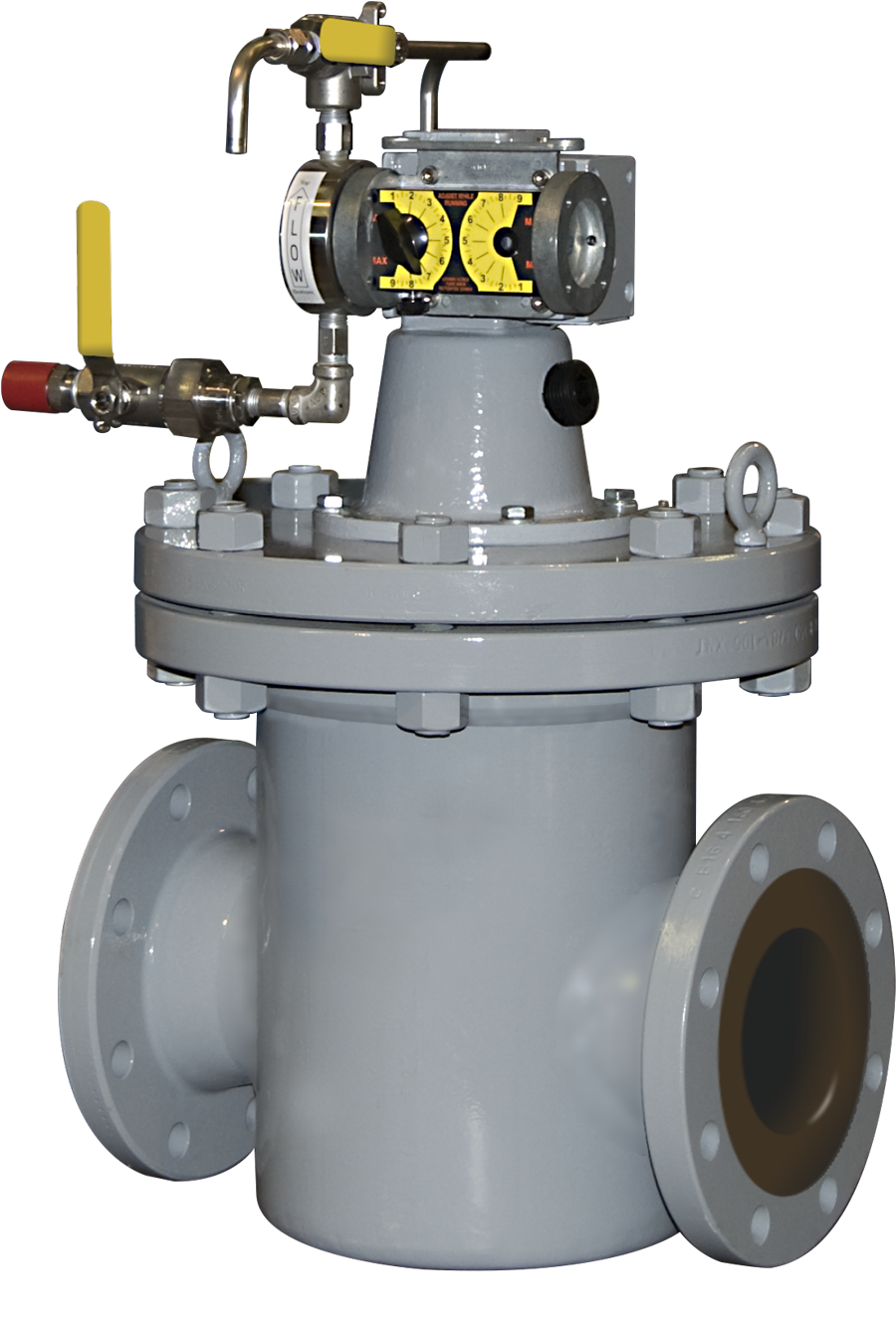

Hammonds Additive Injection Systems ensure fleet operations run smoothly with clean, dependable microbe-free diesel fuel. Additive Injection also provides a fuel which lubricates vital engine parts and provides for less maintenance and downtime. Hammonds offers a variety of systems designed for different flow rates, additive requirements and injection ratios. Additives are delivered on-spec and added directly into the flowing fuel for precise blending.

The INDUSTRY LEADER in additive injection for over 30 years.

Over 10,000 Systems Installed WORLDWIDE

- Flow of fuel is the only power required

- Precise and even blend of additive and fuel

- Single or multiple additive injection units

- A system to fit at any point in the refueling process